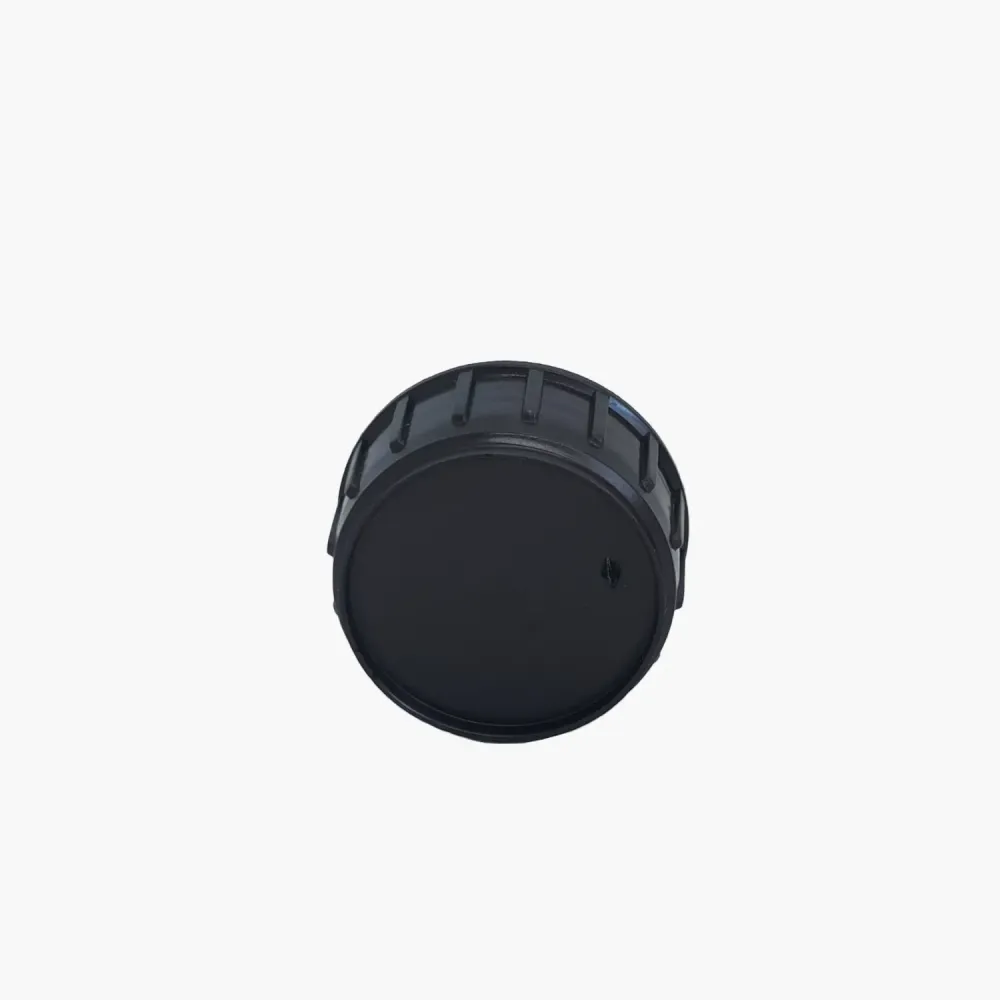

Canister Cap Production Process

Plastic Drum Cap Manufacturing Process

Plastic Drum Cap Manufacturing Process: Quality and Safety Standards

The manufacturing process of plastic drum caps is carried out in compliance with high quality and safety standards. This process ensures the durability and sealing properties of the caps. Each stage of production is carefully planned and executed, from material selection to mold production, injection molding, and quality control processes.

1. Material Selection

The materials used in the production of plastic drum caps are crucial for the durability and performance of the caps. High-density polyethylene (HDPE) and polypropylene (PP) are commonly preferred for their quality. These materials provide resistance to chemicals, UV rays, and mechanical wear, ensuring the longevity of the caps.

2. Mold Production

Mold production allows plastic drum caps to be manufactured in the desired shape and size. Specially designed molds are used in injection molding machines to produce the caps with precision and consistency. High-precision CNC machines are employed in the mold production process.

3. Injection Molding

Injection molding involves shaping the caps by injecting plastic material into the molds. In this stage, plastic is melted under high pressure and temperature and then injected into the molds. Once cooled, the caps are removed and move on to the next stage.

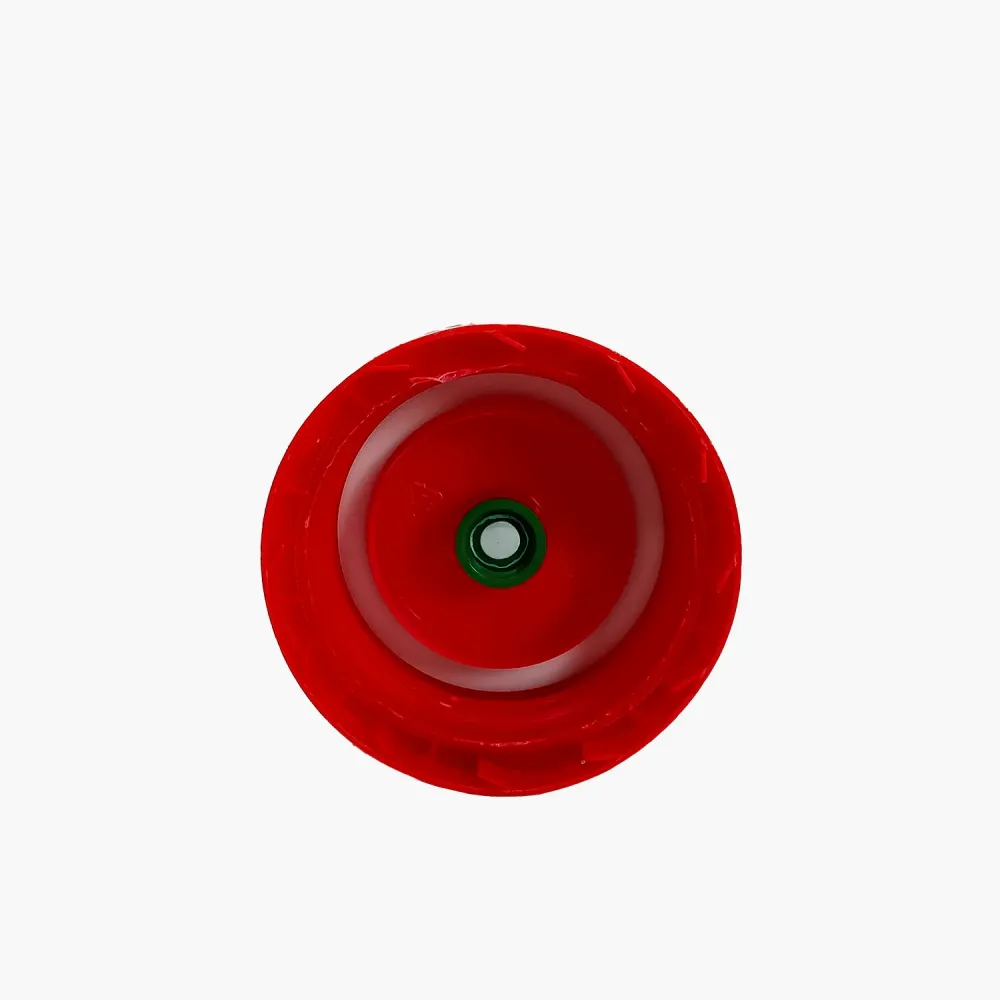

4. Assembly and Additional Components

Some plastic drum caps come with additional components such as gaskets, safety seals, or locking mechanisms. These components are added during the assembly process, enhancing the functionality of the caps. The assembly process requires high precision and attention to detail.

5. Quality Control

At the end of the production process, plastic drum caps undergo a thorough quality control inspection. The caps are tested for sealing, durability, and overall quality. Each cap is subjected to a sealing test to ensure safety during transport and storage.

6. Packaging and Shipping

After passing quality control, the caps are carefully packaged using suitable methods to prepare them for shipment. Special care is taken to prevent damage during packaging, ensuring that the caps reach customers in perfect condition.

In this article, we have outlined the step-by-step process of plastic drum cap manufacturing. At CMF CAP, we produce caps in line with superior quality standards and provide reliable products to our customers. You can explore our website for caps that suit your needs and obtain more detailed information.

Türkçe

Türkçe ENGLISH

ENGLISH РУССКИЙ

РУССКИЙ