Everything You Need to Know About Foil-Lined Caps

What Are Foil-Lined Caps?

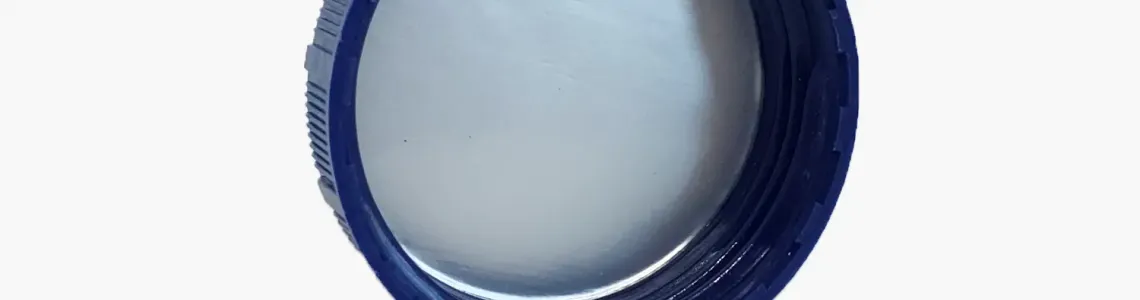

Foil-lined caps are a type of cap used primarily in the food and beverage industry. These caps are equipped with foil layers that provide an additional layer of security and protection for sealed products. Foil-lined caps are designed to preserve the freshness of products, prevent leaks, and protect the products from external factors.

Foil-lined caps generally have an inner surface covered with foil materials. When the cap is opened, the foil layer is usually torn or removed, indicating that the product has not been previously opened or damaged.

How Are Foil-Lined Caps Used?

Foil-lined caps are typically used as follows:

- Placing the Caps: The cap is placed on the mouth of the product to fit snugly. The foil layer tightly seals the mouth of the product within the cap.

- Opening the Caps: When the cap is opened, the foil layer is usually torn or removed. This indicates whether the product has been previously opened.

- Closing the Caps: After use, the cap should be tightly replaced to ensure the product remains fresh and secure.

Applications of Foil-Lined Caps

Foil-lined caps are used in various industries and products:

- Food Industry: Used in food products such as yogurt, milk, sauces, and jams to preserve freshness and prevent contamination.

- Beverage Industry: Used in bottled beverages, especially fruit juices and carbonated drinks.

- Chemical Products: Used in some chemical products for safety and leak prevention.

Features of Foil-Lined Caps

- Protection and Security: Foil-lined caps help protect products from external factors and ensure the product remains fresh.

- Leak Prevention: The foil layer helps prevent leakage from sealed products.

- Tamper Evidence: The foil layer indicates whether the product has been opened or tampered with.

- Durability: Typically made from durable materials, ensuring long-term use.

Manufacturing Process of Foil-Lined Caps

The manufacturing process for foil-lined caps generally includes the following stages:

- Design: The design of the caps is created. During this process, the thickness of the foil layer and details of the cap structure are determined.

- Material Selection: Suitable materials for foil-lined caps are selected. Foil layers are usually made from aluminum or plastic materials.

- Mold and Die Production: Molds and dies are produced to shape the caps and foil layers.

- Production: Caps are produced along with foil layers. Quality control tests are conducted during production.

- Assembly: Caps are assembled with foil layers during the assembly stage, and necessary tests are performed.

- Packaging and Distribution: Caps are packaged and prepared for distribution. Packaging is done to ensure product safety.

Environmental Features of Foil-Lined Caps

Some foil-lined caps are made from environmentally friendly materials. By using recyclable materials, the aim is to reduce environmental impact. Additionally, the design of foil caps helps reduce waste as it ensures products remain fresh for longer periods.

Quality Standards for Foil-Lined Caps

Foil-lined caps are produced according to various quality standards:

- ISO 22000: Sets international standards for food safety management systems.

- FDA Approval: Guarantees that foil-lined caps are suitable for contact with food.

Frequently Asked Questions About Foil-Lined Caps

What is the lifespan of foil-lined caps?

The lifespan of foil-lined caps depends on the materials used and the conditions of use. Generally, caps are designed to last for a long time. It is recommended to regularly check the caps and replace them if necessary.

How are foil-lined caps cleaned?

Foil-lined caps are typically not cleaned, as the foil layer is single-use. However, caps should be regularly checked to maintain environmental hygiene.

Are foil-lined caps suitable for all types of products?

Foil-lined caps are specifically designed for food and beverage products and may not be suitable for all types of products. It is important to select the appropriate type of cap based on the intended use. Foil-lined caps can also be used for chemical products, but it should be ensured that the caps are compatible with the chemical substances.

Türkçe

Türkçe ENGLISH

ENGLISH РУССКИЙ

РУССКИЙ